1

/

of

3

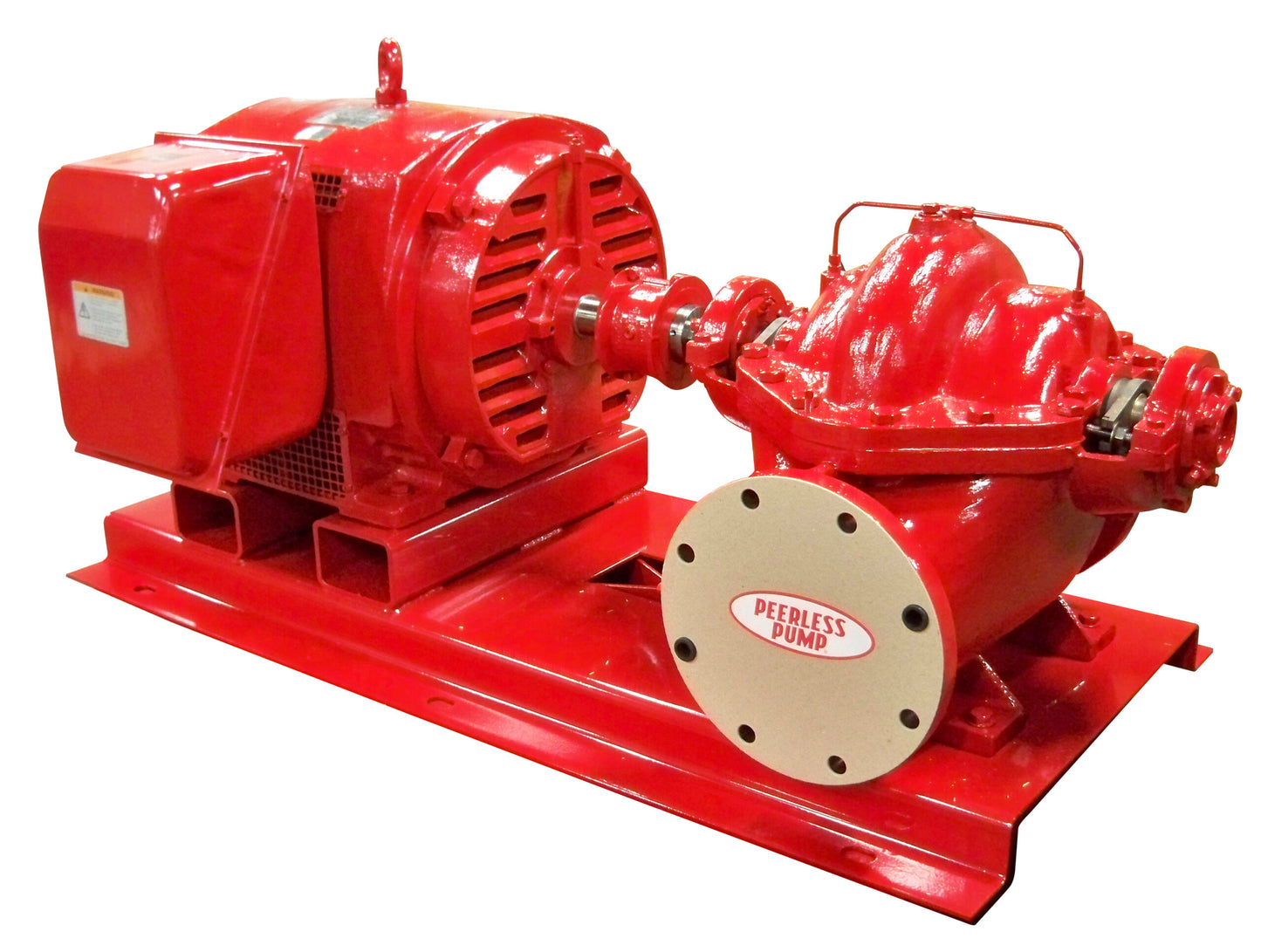

Peerless Pumps

Fire Pumps Horizontal Split Case (AEF Series) – Peerless

Fire Pumps Horizontal Split Case (AEF Series) – Peerless

Variant Description

Variant Description

Variant Dimensions

Variant Dimensions

Share

Applications:

- Commercial Building

- Industrial Facilities

- Energy Facilities

- Oil & Gas Facilities

- Power Plants

For specific technical details, configurations, and compatibility, please to refer to Peerless Fire Pumps Horizontal Split Case (AEF Series) product documentation https://www.peerlesspump.com/products/fire/aef/ or send us an email at our contact us page for more details and quotation.

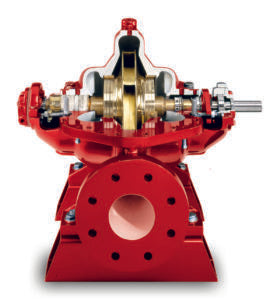

- The casing material is high-density cast iron, minimum tensile strength 35,000 psi. To provide permanent alignment of bearings and all rotating parts, Peerless Pump casts the bearing bracket supports as a part of the lower casing half.

- Renewable bronze casing rings provide sealing for minimum recirculation between the suction and discharge areas of the casing.

- The double-suction impeller is a single cast-bronze piece. Dynamic balancing gives the impeller vibration-free hydraulic and mechanical performance. The balancing also provides a longer bearing life and mechanical seal life. Keyed to the shaft with an 18-8 stainless steel key, the impeller aligns axially with threaded shaft sleeves.

- Packed stuffing boxes hold a minimum of five packing rings with water seal piping and lantern rings. Split glands made of 304 stainless steel facilitate removal for repacking. The gland bolts are swing-type and made of steel with 18-8 stainless steel nuts.

- As standard, the upper casing features a tapped and plugged seal flush connection.

- Replaceable bronze shaft sleeves protect the carbon steel shaft through the stuffing box. The 304 stainless steel shaft sleeves extend beyond the packing glands for maximum shaft protection. O-rings seal the sleeves.

- The bearings are single-row, deep-groove ball-type, and grease-lubricated. Their average life is 100,000 hours. Double-row, outboard thrust bearings are optional.

| Capacities | 250-5,000 gpm (57-1,136 m3/hr) |

| Head | 92 to 664 feet (28-202 m) |

| Pressure | 40-288 psi (2.75-19.8 bar) |

| Horsepower | Up to 1,000 hp (745 kW) |

| Temperature | Ambient within the limits for satisfactory equipment operation |

| Drives | Electric motors, diesel engines |

| Liquids | Potable/non-potable water, salt water |

| Materials | Cast iron, bronze fitted as standard. Optional materials available for sea water applications. |